Turnkey Projects

BF Slag Processing

For new processing technology of BF slag—ultrafine slag powder technology, Archon Group, and our partners are capable of undertaking projects of any capacity including engineering, design, equipment supply, supervision, training, and maintenance on EPS, EPC or Turnkey basis.

This new technology has been developed to use the slag from the Blast Furnace which is ground into an ultrafine powder to be added to concrete. The result is a sustainable, upcycled aggregrate product with lower cost and less environmental impact than other aggregrates.

The maximum theoretical value of slag ultrafine powder to substitute cement for making concrete can be as high as 90%.

According to laboratory trials and actual use in China as well as in America and Europe, the mechanical property and the durability index is better than normal concrete. In practical application, normally 20% – 50% ultrafine BF slag powder is blended to make concrete resulting in savings of US$ 4 -5 USD per cubic meter. Hence, BF slag in the form of ultrafine powder is the best choice for use and it features less investment and yet yielding quick and high returns.

Industrial Furnaces

Over the past few years, Archon Group and our partners have made continuous and sustained efforts in areas of design, engineering, technology development, refractory and equipment supply, construction, management & supervision, related to industrial furnaces to be executed on a turnkey basis.

For many years, we have been providing the optimal design, advanced automation systems and high-quality project contract management plans to all global clients. Today, our activities cover the full spectrum of the market covering iron and steel, non-ferrous metallurgy, machinery, petrochemical, building materials, thermal power generation, etc.

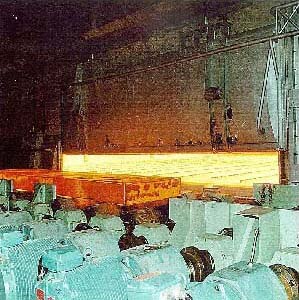

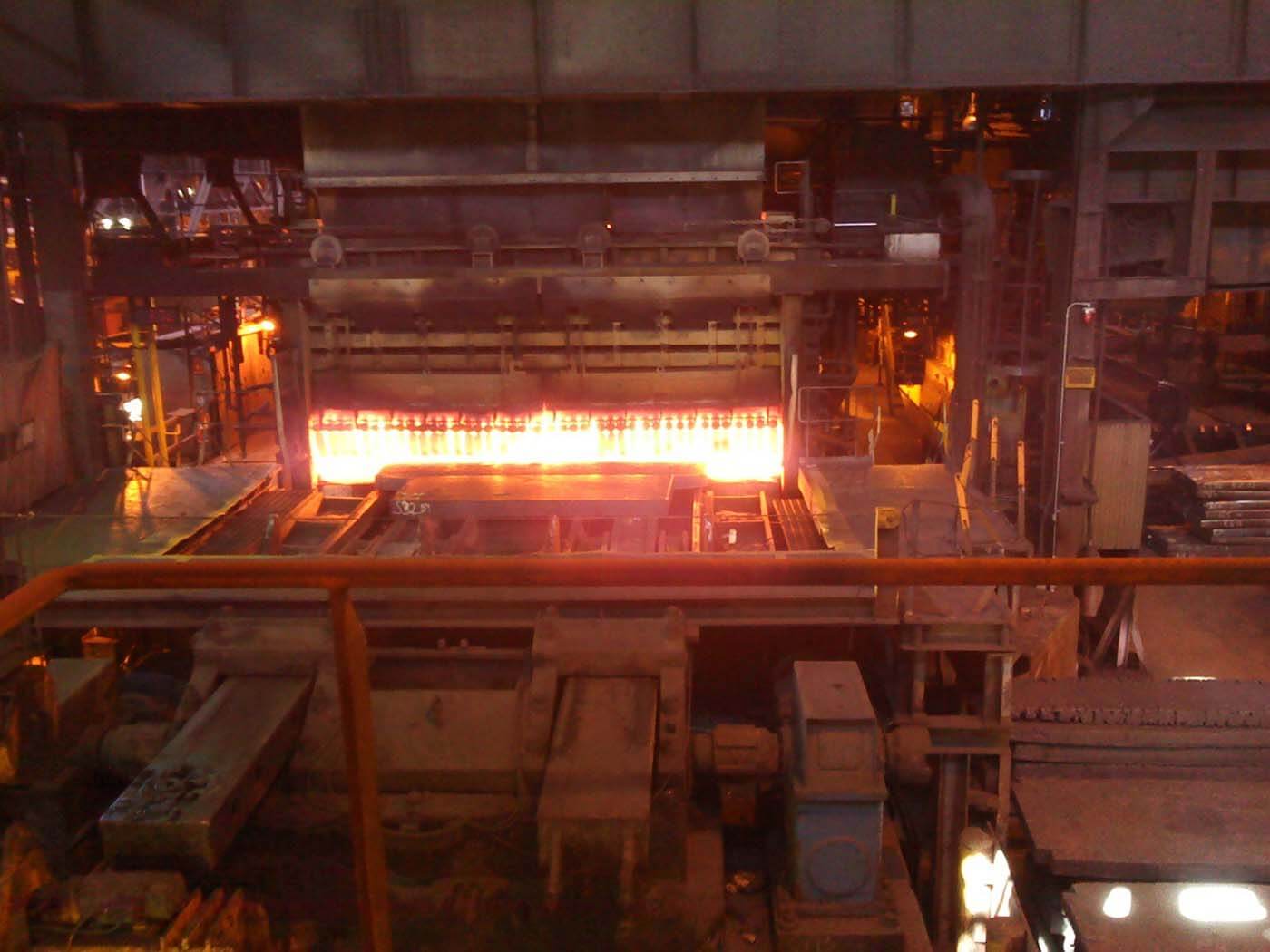

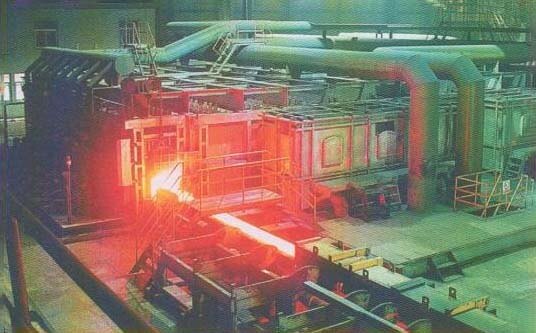

Reheating Furnace

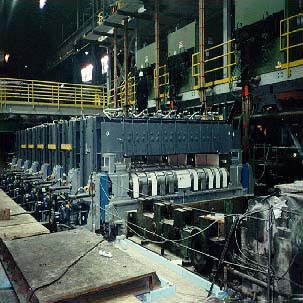

1. Walking beam type reheating furnaces

Billet / bloom reheating furnace

- For Section Steel Mill

- Sectional area (S.A.) of billet: 120mmx120mm~200mmx200mm

- Sectional area of bloom: 200mmx200mm~400mmx400mm

- For Bar and Wire Rod Mill

- Overhung roller table inside the furnace, side charging and side discharging, sectional area: 100x100mm~200x200mm

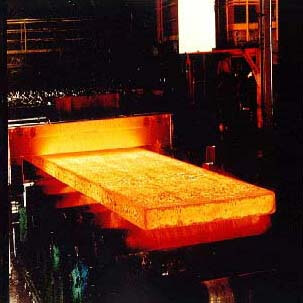

Slab reheating furnace

- Single row & double rows charging

- Maximum output of 300 tph (cold charging)

- Sectional area: thickness 130-300mm, width 900-2000mm, length 5000-12000mm

2. Walking hearth type / Pusher type reheating furnaces

- For Bar and Wire Rod Mill

- Section area of billet: 100x100mm~120x120mm

- Overhung roller table, side-charging, side-discharging, walking hearth type

- Furnace output is up to 120t/h

3. Pusher type reheating furnaces

- For various dimensions of billets or slabs

- Pusher type, top & bottom-firing

- Less investment and faster construction

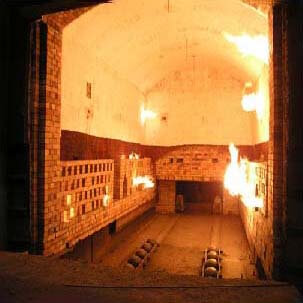

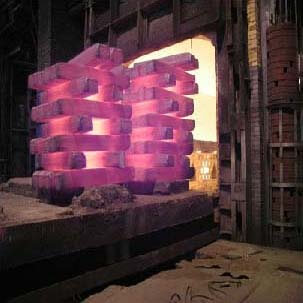

4. Car Bottom Reheating Furnaces and Heat Treatment Furnaces

Car bottom furnaces (bogie hearth furnaces) are operated in discontinuous type for reheating or heat treatment of heavy steel materials or forged pieces. Refractory bricks or fibers can be used for the inner liner of car bottom furnaces.

5. Roller Hearth Type Furnaces

- Normalizing, quenching treatment of hot rolling plates

- Radiant tube with a nitrogen atmosphere

- Maximum furnace length~90m

6. Rotary Hearth Type Reheating Furnaces

It’s for reheat or heat treatment of shaped steel, such as wheels, axles, etc.

7. Tunnel reheating furnaces

- Reheating of continuous casting thin slab

- Thickness of slab: 70~80mm

8. Electric Induction Furnace

- Electric heater is made up of inductor coils

- Discharging temperature: 1050 ~ 1150ºC

9. Bell-type annealing furnace

- Annealing treatment to strip coil

- With protective atmosphere

Project Construction

By using an advanced engineering management system, we remain adaptable to the dynamic market of overseas projects. professionals in engineering management having the latest skills, technical experts in metallurgical engineering construction, and finally translators with rich experience in overseas projects trained in rigorous project management.

While the global contracting market is fiercely competitive, the Archon Group and our partners have developed a sound base with complete contract management capability for overseas projects. We commit to not only strict self-management and self-reliance but also consider all social forces.

Archon Group and our partners embody principles of providing honest service to its customers, have comprehensive strength and years of experience in overseas project contracts undertaking total contract & sub-contract projects of large and medium-size in the metallurgical industry with high quality, engineering supervision, and technical services ranging from design, supply & manufacture, including civil works, structures, equipment, electrics, automation and instrumentation, and installation of project works.